The dew point of the dehumidifier can reach -70 °C, shorten the drying time, improve the drying efficiency, and the residual moisture content can be less than 20ppm.

The first dryer with SCADA technology in China, remote control, adjustment of technical parameters according to the actual situation, online detection, and prediction of faults in advance.

Dew point switching technology can set different dew points according to the drying requirements of different materials to minimize energy consumption.

Compared with the same output of honeycomb dehumidifier, Jinyue molecular sieve dehumidifier saves 18%-60% in energy consumption. (This is based on thousands of experimental reports and feedback from customers, testing real data)

Compared with the Jinyue standard molecular sieve dehumidifier, the Jinyue modular dehumidification dryer saves about 25% energy consumption.

1. This system is divided into multiple identical module dryers, which can work independently and do not affect each other.

2. Multiple modules of this system share an independent electronic control system, using PROFINET communication, quickly connect to form a system.

3. According to the number of barrels used, automatically judge the number of module dryers opened to save energy.

4. According to the dew point situation, automatically determine whether there is a module dryer that needs to be regenerated to save energy.

5. According to the temperature situation, the regenerative heat can be extracted into the entire drying system to recover the regenerative heat energy.

6. If the individual module fails, it will not affect the whole system and can be repaired quickly.

7. If the production is expanded in the future, the number of modules and barrels can be directly increased, without the need to add the whole set of equipment, saving costs.

Warning lights

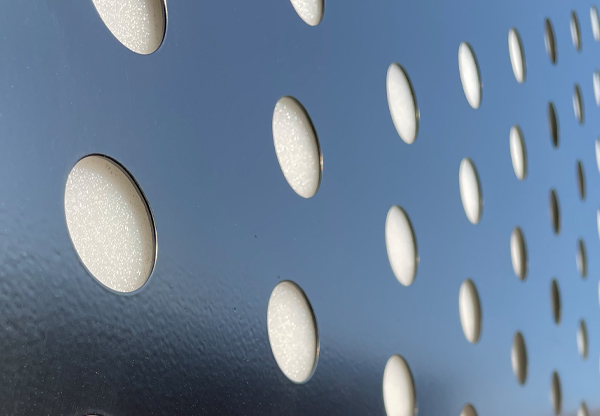

Large view cleaning window

氣閥7A34A9B8103F4C99B38CCDF576DDEA64.png)

Outlet

Sampling port

部.png)

All stainless steel pipe connection

Remote control system

Modular case

Copyright 2019-2021 JIN MACHINE 某ICP備00000000號-1